HOME

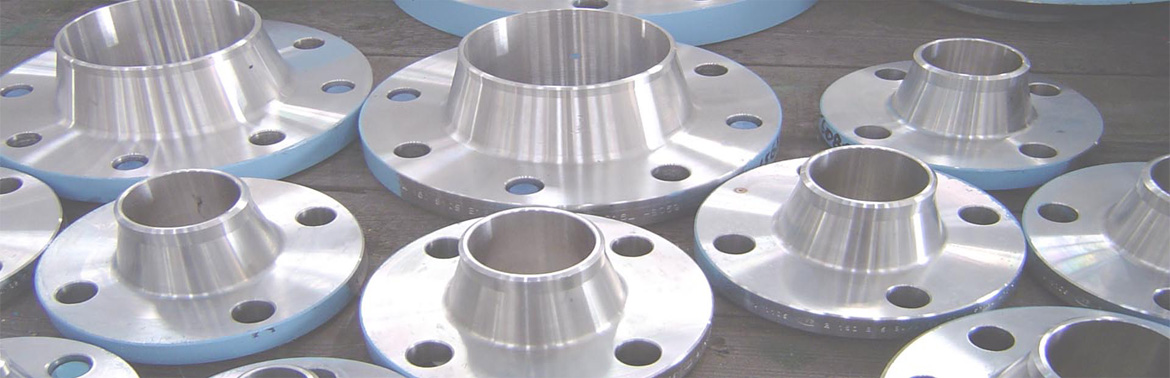

We take the opportunity to introduce ourselves as one of the leading “MANUFACTURERS AND SUPPLIERS OF OPEN AND CLOSE DIE FORGED COMPONENTS” for refineries, oilfields, petro chemical, power plants and other Industrial Applications. We are also a registered vendor with Engineers India Ltd, GSPL, HPCL, IOCL & ONGC for the supply of Forged Flanges in Carbon, Alloy, Stainless Steel Duplex Steel, INCONEL® which is a nickel-chromium alloy and MONEL® which a nickel-copper alloy Steels .Our skilled and experienced work force together with a highly professional environment has been the instrument of excellence. We are capable of forging various specialize form of forging used in various engineering applications. We are also suppliers of forgings to some European, American and Gulf Companies.

Our Capacity

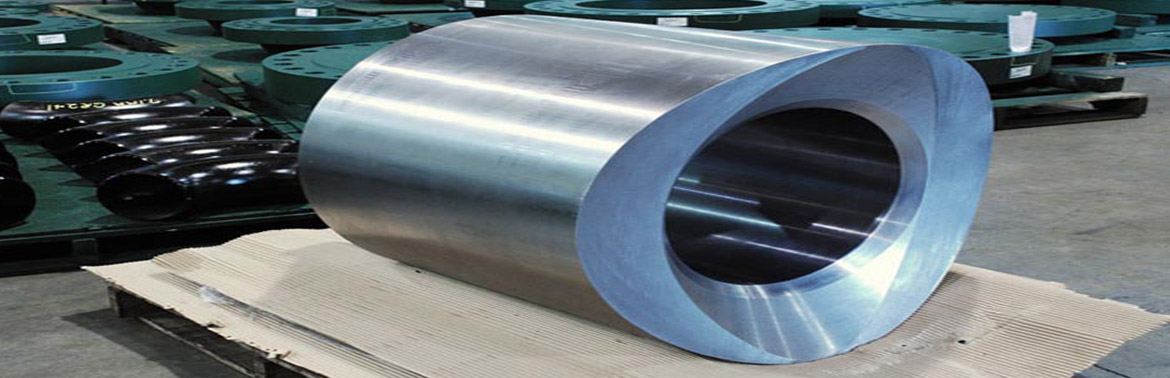

Our Capacity of producing forgings ranges from 0.500 Kg. to 50 Kg in Close Die Forging with a production range of maximum OD Size up to 485 mm. In Open Forging our production ranges up to a single piece weighting 4.5 MT. We are capable of forging Stepped Shafts, Plain Shafts and producing Rings type forgings of Maximum Sizes up to a diameter of 2000 mm (max weight 3500Kg).

Testing Facility

We are an ISO 9001:2015, 14001:2015 ,45001:2018& PED certified company .We are committed to satisfy our customers through quality products. We have adopted a quality policy and also have the requisite equipment / sources to test quality from the very first stage to the final stage. Our inhouse Physical Lab is calibrated and witnessed by TPI, with the following testing facilities

Inhouse Testing Equipment

1- PMI Testing.

2- MPI Testing.

3- Liquid Penetrating Testing

4- Ultasonic Testing.

5- Impact( Both ASTM & BS Std ) Testing.

6- Mechanical Testing Digital As well Analogy UTM.

We are also equipped with a heat treatment furnaces with a capacity of 3 tons &5 tons equipped with digital Data logger.